The client operates two unloaders at its facility in South America. One of the unloaders is experiencing chronic fatigue cracking. The unloader was shut down for operation several times for emergency repairs of critical fatigue cracks. The client was concerned with the structural reliability of the unloader, and crack repairs and inspections were disruptive to the operation. The client retained Liftech to provide engineering…

Category: Crane Assessment Projects

POLA STS Crane Portal Frame Fatigue Study

Fatigue cracks were found in the portal beams of Noell cranes at Pier 400, Los Angeles. Cracking had occurred most frequently at the end of an internal stiffener where the portal beam tapered, and at seafastening lugs that remain on the cranes at the portal-to-leg connections. Other cracking had occurred in the main equalizer brackets.

San Antonio Terminal Paceco Crane Damage Assessment and Repair

Two Paceco cranes operated by San Antonio Terminal Internacional at their San Antonio Terminal in Chile suffered damage when the cranes were struck by departing ships in the aftermath of the February 2010 magnitude 8.8 earthquake. One crane suffered significant damage to the boom and the portal frame. The other crane suffered significant damage to the boom and the trolley.

Felixstowe RMG Design Review

Felixstowe Dock and Railway Company purchased one rail mounted gantry (RMG) crane from ZPMC. Liftech reviewed the structural design, structural fabrication, and seafastening design and installation.

Freeport Hyundai Crane Damage Assessment and Repair

A tornado damaged six Hyundai monogirder cranes and toppled another. Liftech assessed the damage to the untoppled cranes and assisted with engineering for the repairs. Hyundai Crane 9 suffered severe damage when it collided with Crane 10. The boom detached from the right lower hinge pin, the upper hinge broke off, the forestay apex connection plate bent, and the boom rotated more than 45 degrees.

Freeport OMG Crane Damage Assessment

The forestays of an Officine Meccaniche Galileo (OMG) crane were twisted and became entangled as a result of Hurricane Frances in September 2004. Liftech was retained to assist with the assessment and repair of the forestay system.

Crane Damage Assessment, Pusan, Korea

On September 12, 2003, Typhoon Maemi struck the Dongbu Pusan Container Terminal causing the sequential collapse of six out of seven HHI container cranes at the terminal. Liftech was retained to assist with the damage investigation and to provide expert opinion on technical issues related to the design and fabrication of the stowage hardware on the crane and in the wharf.

Bauxite Unloader Study

Two bauxite unloaders of identical design have been operating for over 50 years. The operator wished to continue operations for another 15 years. Liftech analyzed the crane structure to assess the fatigue life for continued operations.

Revolver Crane Review

Liftech has been involved in review and modification of several revolver cranes. Our revolver crane work includes: • Conversion of an IHI revolver crane from shore power to diesel power and relocation to another location

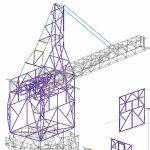

Rio Tinto Alcan Unloader Structure Assessment

The owner of two 40-year-old bauxite unloaders in Quebec, Canada, was evaluating whether to continue operating, to upgrade, or to replace the existing unloaders. As part of the feasibility study, the owner needed a condition assessment of the unloaders by an independent consultant. Liftech performed an on-site visual assessment of the structural condition of the unloaders.